measurement of gear tooth thickness slideshare|gear tooth thickness problems : online sales Gears are precisely measured and inspected to evaluate factors such as pitch errors, runout, profile accuracy, and tooth thickness. Common inspection methods include using vernier calipers, comparators, and optical . WEB2 de fev. de 2023 · Dois se feriram na tentativa de homicídio. Os disparos foram feitos na Avenida Ayrton Senna da Silva, no bairro Xixová, em frente ao shopping. Segundo o documento do TJ-SP os dois atiradores tentaram matar as vítimas “por motivo fútil e utilizando-se de recurso que dificultou a defesa das vítimas, mediante disparos de arma .

{plog:ftitle_list}

26 de set. de 2023 · Mallorca x Barcelona se enfrentam hoje [26/09]! Veja o nosso palpite, saiba onde assistir, que horas vai passar e as prováveis escalações . Athletic Club. Ath. Empate. E. 26/08/2023. Granada CF. Gra. 3. X. 2. Mallorca. Mal. Derrota. D. 18/08/2023. Mallorca. Mal. 0. X. 1. . Mallorca x Barcelona - Onde assistir. Serviço de streaming .

The key aspects covered include defining gear tooth features, common errors in spur gears during manufacturing, and methods for measuring specific gear elements like .Gears are precisely measured and inspected to evaluate factors such as .Rolling gear tests using a Parkinson gear tester can efficiently measure variations . Gears are precisely measured and inspected to evaluate factors such as pitch errors, runout, profile accuracy, and tooth thickness. Common inspection methods include using vernier calipers, comparators, and optical .

Several methods for measuring gear tooth thickness are described, including using a gear tooth Vernier caliper, constant chord method, base tangent method, and .

Tooth Thickness is a page to learn methods of measurement of gear tooth. This is a part of KHK's Gear Technical Reference for all machine designers.Inspection and Measurement of Tooth Thickness - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses methods for measuring .

For this article, we for measurements in the axial plane are detailed in Table 8, and those for will discuss chordal tooth thickness measurements. The chordal tooth thickness measurement . There are three methods for determining this value: chordal tooth thickness measurement, span measurement, and over-pin or ball measurement. For this article, we .Tooth Thickness - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses different methods for measuring gears, including measurement over pins, vernier gear tooth . Rolling gear tests using a Parkinson gear tester can efficiently measure variations in center distance to identify errors. Individual gear elements like tooth thickness are measured using methods like a gear tooth Vernier .

tooth thickness of gear formula

There are three methods for determining this value: chordal tooth thickness measurement, span measurement, and over pin or ball measurement. For this article, we will discuss chordal tooth thickness . 7-Gear Measurement-P1.pdf - Download as a PDF or view online for free . If we assume the tooth thickness as t2 and width ‘t1 then Back lash = t1- t1 Lecture (7) – Mechanical Measurements 11. 11 Gear Errors 1. Profile . The document discusses gear metrology and measurement methods. It defines various gear terminology such as pitch diameter, addendum, dedendum, and tooth thickness. It describes two main methods for .

For gears, it describes measuring runout, pitch, profile, backlash, tooth thickness, and alignment using devices like dial indicators, involute measuring machines, and angular measurement techniques. The document . For this article, we will discuss chordal tooth thickness measurements. The chordal tooth thickness measurement method uses a tooth caliper that is referenced from the gear’s tip diameter. The thickness is measured at the reference circle as detailed in Figure 1. Figure 1: Chordal tooth thickness method. For spur gears, the formulas to . Alignment of individual teeth can be analyzed mathematically or through functional testing. Rolling gear tests using a Parkinson gear tester can efficiently measure variations in center distance to identify errors. Individual gear elements like tooth thickness are measured using methods like a gear tooth Vernier caliper or constant chord method. (Refer Fig. 15.15). It is used to measure the thickness of gear teeth at the pitch line or chordal.thickness of teeth and the distance from the top of a tooth to the chord. The thickness of a tooth at pitch line and the addendum is measured by an adjustable tongue, each of which is adjusted independently by adjusting screw on graduated bars.

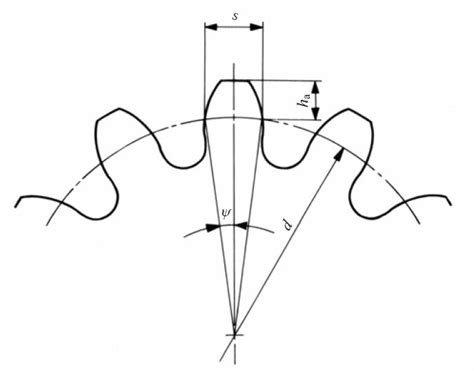

MEASUREMENT OF TOOTH THICKNESS Measurement of Gear Tooth Calipers: • The value of width (w) and addendum height (h) can be obtained as follows. From the figure, AB = w and CD = h. So, AD + BD = w and AD = BD. ⸫ w = 2 × AD From ΔAOD, sin θ = AD / AO ⸫ AD = AO sin θ = R sin θ Angle AOD = θ = 360 / 4N ⸫ θ = 90 / N ⸫θ = R sin (90 .

ANSI/AGMA 2002-D 19 ANSI/AGMA 2002-D19 (Revision of ANSI/AGMA 2002-C16) American National Standard . Tooth Thickness and Backlash Measurement of Cylindrical Involute

Subject - Metrology and Quality ControlChapter - Construction and Working of Gear Tooth Vernier CaliperTimestamps0:00 - Start0:08 - Gear Tooth Vernier Calipe. For larger diameter gears a span measurement or gear tooth calipers can be used. Composite testing can also provide a measurement of gear tooth size. Size measurement is used to provide the correct backlash when the gear is mounted with its mating gear at operating center distance. Measurement of size with micrometer and pins or balls .

Gas Detector distribute

Unit 3 - Download as a PDF or view online for free. 42. ∗ Tooth profile ∗ It is the shape of any side of gear tooth in its cross section ∗ Pitch circle ∗ It is the imaginary circle of gear that rolls without slipping over the circle of its mating gear. ∗ Addendum circle ∗ The circle coincides with the crests (or) tops of teeth. ∗ Dedendum circle (or) Root circle ∗ This circle . Alignment of individual teeth can be analyzed mathematically or through functional testing. Rolling gear tests using a Parkinson gear tester can efficiently measure variations in center distance to identify errors. Individual gear elements like tooth thickness are measured using methods like a gear tooth Vernier caliper or constant chord method. A specific tooth thickness specification limit can be established from the design thickness or from another tooth thickness measurement. The procedures can be used with an established design tooth thickness, or with actual tooth thickness dimensions. The effect of tooth geometric quality variations on tooth thickness dimensions is discussed.

Portable Gas Detector distribute

methods. A specific tooth thickness measurement limit can be established from the design thickness or from another tooth thickness measurement. The procedures can be entered with an established design tooth thickness, or with actual tooth thickness measurements. The effect of tooth geometric quality variations on tooth thickness measurements isTooth thickness refers to the thickness of a single gear tooth. This page explains the methods of calculating the load applied to tooth thickness, the causes of changes in tooth thickness, and methods of measuring tooth . Figure 1: Span measurement over k teeth (spur gear). Figure 1 details the span measurement of a spur gear. As such, the span measurement is on the outside of the teeth. For internal gears, the tooth profile is opposite to that of the external spur gear. As such, the measurement for an internal gear is between the inside of the tooth profiles.

A specific tooth thickness specification limit can be established from the design thickness or from another tooth thickness measurement. The procedures can be used with an established design tooth thickness, or with actual tooth thickness dimensions. . center distance, and tooth deviations in a pinion and gear mesh. FOREWORD [The foreword . These variations cannot be separated from the measurement of tooth thickness. • Therefore, a precise prediction of a measurement result from one method in relation to another method cannot be accurately made, although • the different measuring methods will usually be reasonably consistent. . • A camera based gear tooth measurement . 10/20/2016 23 Gear tooth Vernier Measurement of tooth thickness 45Prof N D Sadaphal The tooth thickness is generally measured at pitch circle •Since the gear tooth thickness varies from the tip to the base circle of the tooth, the instrument must be capable of measuring the tooth thickness at a specified position on the tooth. •The gear . I n order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. There are three methods for determining this value: chordal tooth thickness measurement, span measurement, and over-pin or ball measurement. For this article, we will discuss .

6. Tooth thickness measurement Tooth thickness is generally measured at pitch circle and also in most cases the chordal thickness measurement is carried out .i.e. the chord joining the intersection of the tooth profile with the pitch circle. The methods which are used for measuring. the gear tooth thickness are a) Gear tooth Vernier caliper . 10/20/2016 23 Gear tooth Vernier Measurement of tooth thickness 45Prof N D Sadaphal The tooth thickness is generally measured at pitch circle •Since the gear tooth thickness varies from the tip to the base circle of the tooth, the instrument must be capable of measuring the tooth thickness at a specified position on the tooth. •The gear .

tooth thickness chart

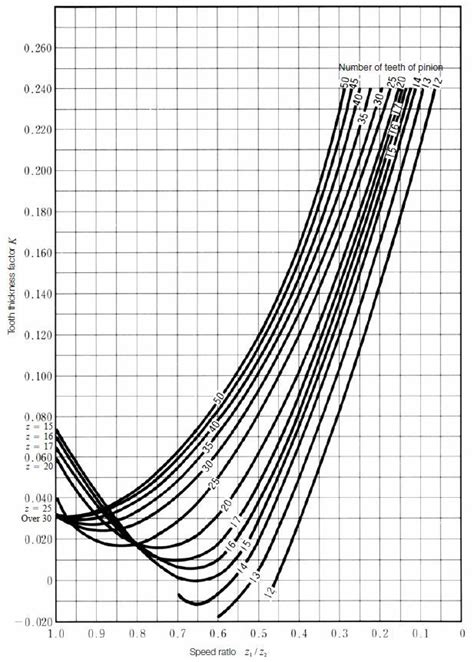

vide detailed measurement information that is solely specific to gears and gear teeth, including thickness, width, tooth thickness and pitch diameter. However, this type of machine does not measure characteristics of parts that gears get mounted on to. For this reason, a more flexible, automated option has become progressively more popular. This approach offers a convenient way to determine the tooth thickness of gears within the capacity of available micrometers. By utilizing specific pins or balls, technicians can accurately measure the distance between gear teeth and ensure adherence to precise specifications. . Composite testing can also provide a measurement of gear tooth size.NOTE 1 : The subscripts 1 and 2 of z 1 and z 2 denote pinion and gear. All calculated values in Table 4.1 are based upon given module m and number of teeth (z 1 and z 2).If instead, the modulem, center distance a and speed ratio i are given, then the number of teeth, z 1 and z 2, would be calculated using theformulas as shown in Table 4.2.. Table 4.2 The Calculations for .ansiagma2002b88r2014-Tooth Thickness Specification and Measurement-This standard establishes the procedures for determining tooth thickness measurements of exte . HOME; PRODUCTS. Publisher Collections; . Appearance of Gear Teeth - Terminology of Wear and Failure . ADD TO CART. ANSI/AGMA 2004-B89 (R2006) Gear Materials and Heat Treatment .

8. The various measurement methods can lead to slightly different tooth thickness results on any given gear. Variations in profile, pitch, helix, runout, and measurement location will have different effects depending on the measuring method employed, see Table.

how to calculate tooth thickness

web11 de jul. de 2023 · Discover the best things to do in Manhattan, from iconic landmarks .

measurement of gear tooth thickness slideshare|gear tooth thickness problems